Features of balanced bellows expansion joints

Operation principle of balanced expansion joints consists in artificial creation of balancing force directed towards the separating force from pressure action on the walls of the bellows corrugations. The balancing force can be created both mechanically - using a spring-lever mechanism that keeps the bellows from stretching under action of pressure, and hydraulically (pneumatically) - using a balancing bellows and a system of hinged unloading rods that absorb the separating force of the main (working) bellows.

Kompensator SPE, JSC manufactures various designs of balanced bellows expansion joints that take up deformations both in strictly axial direction and with simultaneous effect of deformations in axial direction, a direction perpendicular to the expansion joint axis, and angular deformations without transferring the separating force of the bellows to fixed supports and equipment.

Taking into account the design complexity and rather high cost of balanced bellows expansion joints, their use in pipeline systems is advisable in a confined space, when it is not possible for various reasons to install fixed supports capable of absorbing the loads from the expansion joint separating forces. Balanced bellows expansion joints are also used in cases where the mating equipment (pumps, turbines, etc.) has limitations by loads acting on the connecting element (flanges, body, etc.).

Balanced bellows expansion joints are more efficient than conventional expansion joints and they can:

- balance deformation of any type, including combination of axial, angular and lateral displacements;

- take up and not transfer to the fixed supports the separating forces resulting from excessive pressure;

- withstand high pressures and temperatures of working medium.

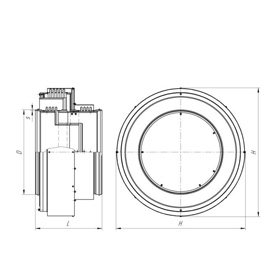

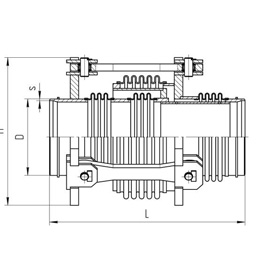

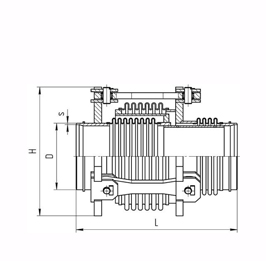

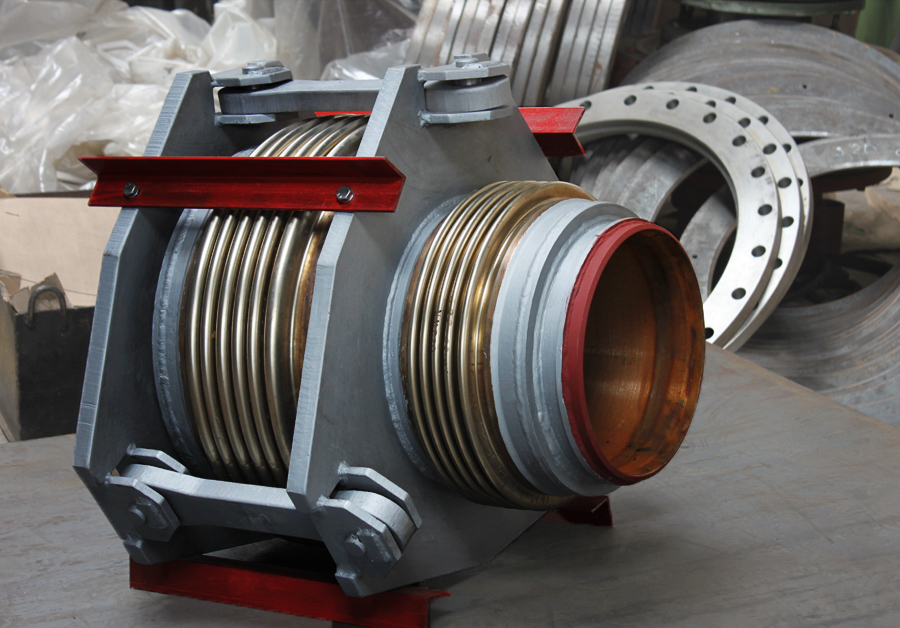

Axial balanced expansion joint design

Standard design of axial balanced bellows expansion joint is a structure consisting of three bellows, connected in series through flanges, and a system of hinged unloading rods connecting the bellows flanges in pairs. The rods connect the bellows flanges in such a way that with the axial thermal elongation of the pipeline section by λ, each outermost bellows will be compressed by λ/2, and the intermediate bellows will be stretched by λ, thereby compensating for the pipeline section length change. Diameter of the intermediate bellows is selected so that its effective area is √2 times larger than the effective area of the two outermost bellows. Thus, the separating force arising in the outermost bellows is balanced through the rod system with the separating force of the intermediate bellows and is not transferred to the fixed supports and mating equipment.

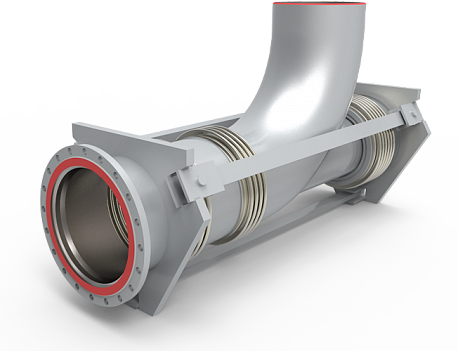

Significant disadvantage of this design is high labor intensity of its manufacture and, consequently, the high self-cost, as well as large dimensions. To reduce the size and self-cost of three-bellows balanced expansion joints, the flange-rod system can be replaced with a flange-branch piece system. Additional advantage of such design with use of branch pieces is a significant reduction of hydraulic resistance, which allows it to be used at elevated temperatures and high flow rates of the conducted medium.

Additionally, these versions of balanced bellows expansion joints can be equipped with a system of slats and hinges, which ensures their stable operation when compensating for axial, angular and lateral displacements.

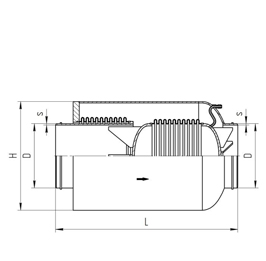

To compensate for thermal deformations of pipelines strictly in the axial direction, when it is not possible to install fixed supports and unbalanced bellows expansion joint cannot be used, Kompensator SPE, JSC manufactures two-bellows balanced expansion joints, one of the bellows of which operates under the action of external pressure and balances the separating force of the second bellows. If it is necessary to increase compensating capacity of the balanced expansion joint, the number of bellows may be increased to four, one pair of bellows of which operates under the action of external pressure.

Kompensator SPE, JSC offers the following types of balanced bellows expansion joints:

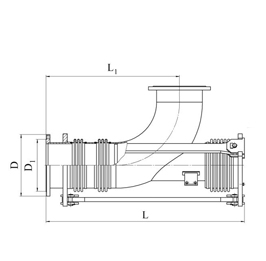

- axial three-bellows balanced expansion joints with guide branch piece and protective casing, type 3ROPK (3РОПК);

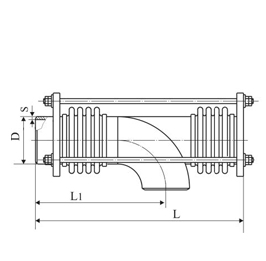

- universal three-bellows balanced expansion joints with welded neck branch pieces, type 3RUPN (3РУПН);

- universal four-bellows balanced expansion joints with welded neck branch pieces, type 4RUPN (4РУПН);

- universal three-bellows balanced expansion joints with a branch, type 3RUOF (3РУОФ);

- universal balanced expansion joints with a branch, type 2RUOP (2РУОП);

- externally pressurized balanced expansion joints, type 2RND (2РНД).

Balanced bellows expansion joints type 3РУПН, 4РУПН, 3РУОФ, 2РНД can be installed directly in pipelines carrying water (delivery and drinking water) under a temperature of up to 150 °С and at a flow rate of up to 8 m/s, oil and oil products under a temperature of up to 450 °С and at a flow rate of up to 8 m/s, as well as steam and gaseous media that do not corrode materials of the expansion joint under a temperature of up to 500 °C and at a flow rate of up to 20 m/s.

Balancaed bellows expansion joints, type 3РОПК can be installed directly in pipelines carrying water (delivery and drinking water) under a temperature of up to 150 °С and at a flow rate exceeding 8 m/s, oil and oil products under a temperature of up to 450 °С and at a flow rate exceeding 8 m/s, as well as steam and gaseous media that do not corrode materials of the expansion joint under a temperature of up to 500 °C and at a flow rate from 20 to 80 m/s.

Разгруженные сильфонные компенсаторы