Features of lateral bellows expansion joints

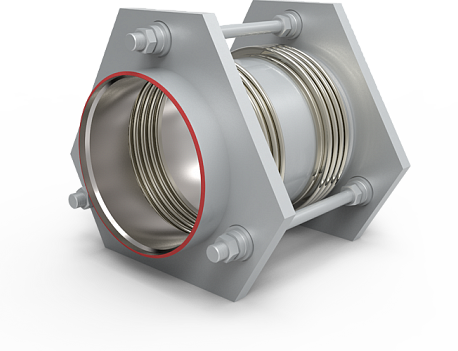

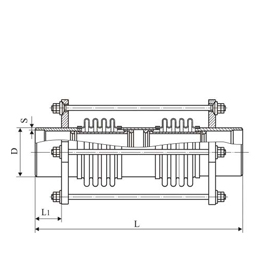

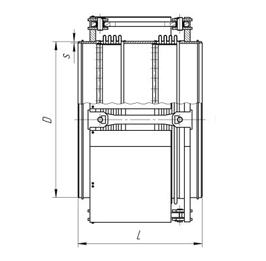

Lateral bellows expansion joint is a hinged structure consisting of a bellows (or two bellows connected to each other through a tube insert), connecting fittings and limiting fittings that prevent the expansion joint length change (lengthening or shortening).

When using two-bellows lateral expansion joints, their compensating capacity is proportionally dependent on the length of the intermediate tube insert:

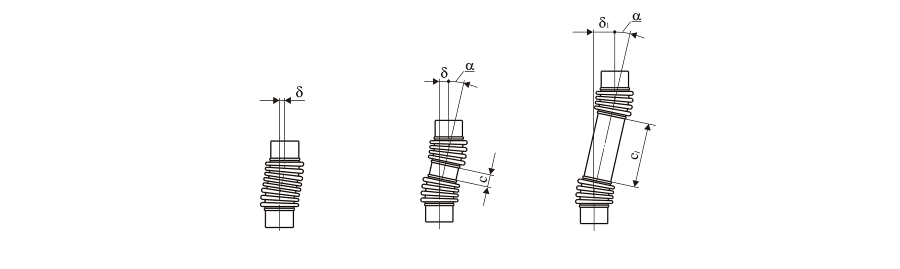

The lateral bellows expansion joint does not take up the angular effect of the connected structures. Hinged design of the limiting fittings of lateral bellows expansion joint allows the bellows to perform only a plane-parallel shift of the expansion joint ends perpendicular to its axis to one or another side within the elastic deformation of the bellows material.

Limiting fittings connected with the connecting branch pieces absorb the separating forces arising from the action of internal pressure on the bellows and do not transfer them to the fixed supports and equipment.

The limiting fittings are hinged rods designed to absorb the separating forces arising from the action of internal pressure and to exclude the expansion joint length change. In addition, the rods shall be designed to withstand action of loads arising in pipeline systems subject to thermal deformations.

They may be equipped with inner guide branch pieces and outer protective casings.

Application of lateral bellows expansion joints

Lateral expansion joint may be replaced with two or three rotary expansion joints, which will provide the same displacements. Likewise, two rotary expansion joints may be replaced with one lateral expansion joint. Lateral expansion joints are used, as a rule, to compensate for small displacements of pipeline elements. For large displacements of the pipeline system elements, two, and in some cases, a system of three rotary expansion joints shall be used to compensate them, providing total compensation for almost any values of lateral displacements of the pipeline system by increasing the length of the straight pipeline section between the rotary bellows expansion joints.

Depending on type of the applied limiting fittings, lateral bellows expansion joints may be manufactured as single-plane, taking up lateral displacements in only one plane, and spatial, taking up lateral displacements in all directions.

Kompensator SPE, JSC offers the following types of lateral bellows expansion joints:

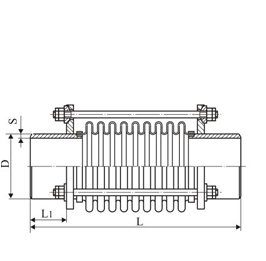

- single-plane lateral expansion joints, type SPPN (СППН);

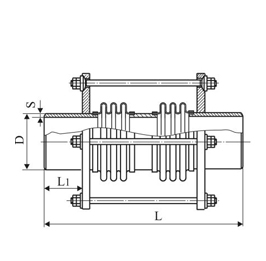

- two-plane two-bellows lateral expansion joints, type 2SPPN (2СППН);

- two-plane two-bellows lateral expansion joints, type 2SPPG (2СППГ);

- two-plane lateral expansion joints, type 2SPPM (2СППМ).

These bellows expansion joints can be installed directly in pipelines carrying water (delivery and drinking water) under a temperature of up to 150 °С and at a flow rate of up to 8 m/s, oil and oil products under a temperature of up to 450 °С and at a flow rate of up to 8 m/s, as well as steam and gaseous media that do not corrode materials of the expansion joint under a temperature of up to 500 °C and at a flow rate of up to 20 m/s.

Lateral bellows expansion joints can be installed directly in pipelines, carrying under a temperature of up to 150 °С and at a flow rate exceeding 8 m/s, as well as steam and gaseous media that do not corrode materials of the expansion joint under a temperature of up to 500 °C and at a flow rate from 20 to 80 m/s provided a branch piece is installed.