The main advantages of bellows compensation devices:

- temperature resistance;

- tightness;

- reliability;

- long service life;

- does not require maintenance;

- easy installation method.

Kompensator SPE, JSC plant has developed and serially manufactured a wide range of bellows compensation device modifications specifically for heat networks.

At Customer’s request, the BCD is equipped with a remote on-line monitoring system (ROMS). The ROM system is designed to monitor condition of heat-insulating layer of polyurethane foam in pre-insulated pipelines and to detect areas with increased insulation moisture.

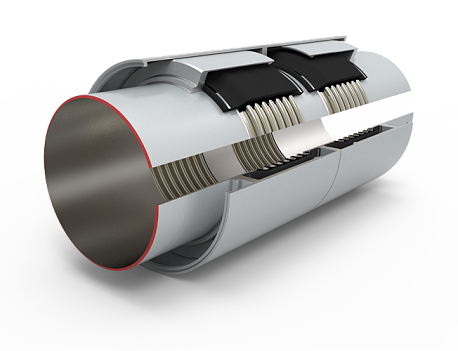

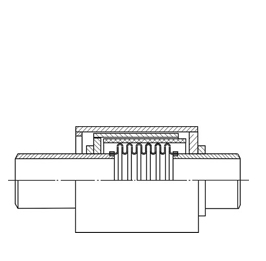

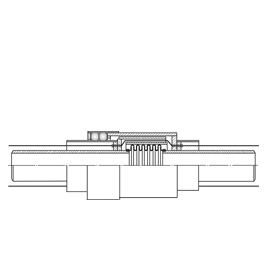

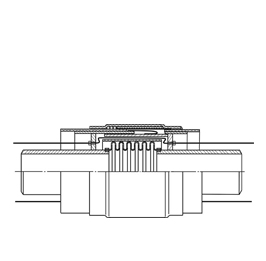

- SCU (BCD), type M can be installed in steel pipelines carrying water under a temperature of up to 200 °C and at a flow rate of up to 6 m/s, as well as steam under a temperature of up to 350 °C and at a flow rate of up to 30 m/s under a rated pressure of up to 25 kgf/cm². It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casing and internal guide supports. The bellows is thermally insulated. Waterproofing of the bellows and factory insulation of the welded neck branch pieces are not provided. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating.

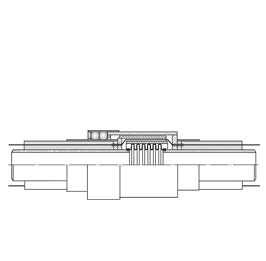

- SCU (BCD), type МP is recommended to be used on pipelines carrying water under a temperature of up to 200 °C at a flow rates over 6 m/s with a closed water intake system and high-quality water treatment, as well as on pipelines carrying steam under a temperature of up to 350 °C and at a flow rate over 30 m/s under a rated pressure of up to 25 kgf/cm². It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casings and internal guide supports. The design provides an internal guide branch piece to reduce hydraulic resistance at high flow rates of the working fluid. The bellows is thermally insulated. Waterproofing of the bellows and factory insulation of the welded neck branch pieces are not provided. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating.

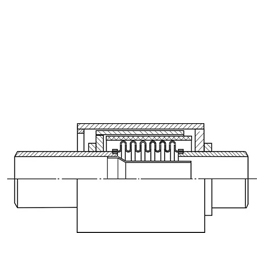

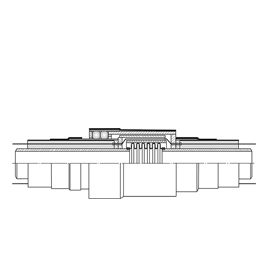

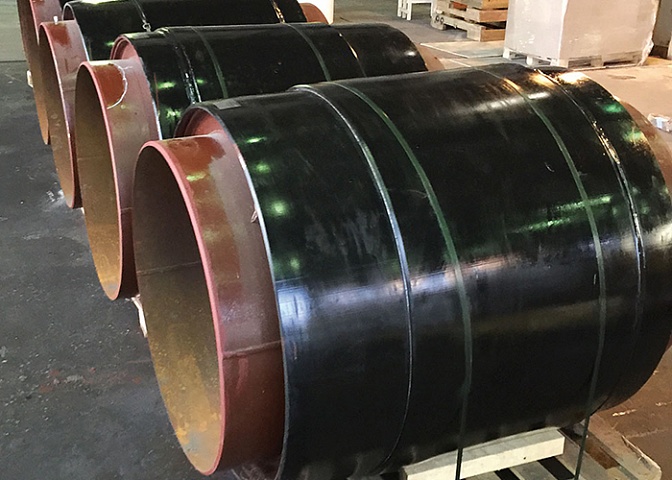

- SCU (BCD) type PPM is designed to compensate for axial thermal deformations of pipelines with industrial polymeric mineral foam thermal insulation with a maximum coolant temperature of up to 150 °C for all methods of their laying, including channelless one. BCD, type PPM can also be used for repairs and new construction of steel pipelines with industrial thermal insulation of autoclave reinforced foam concrete. It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casing and internal guide supports. The bellows is thermally insulated. The inner surface of the BCD is waterproofed from ground water with a stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. Factory insulation of the branch pieces is not provided, there are two alignment sleeves for applying polymeric mineral foam thermal insulation onto the branch pieces after installation of the BCD.

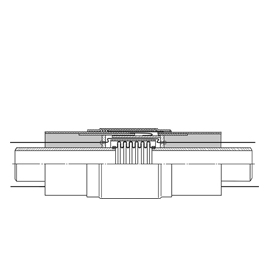

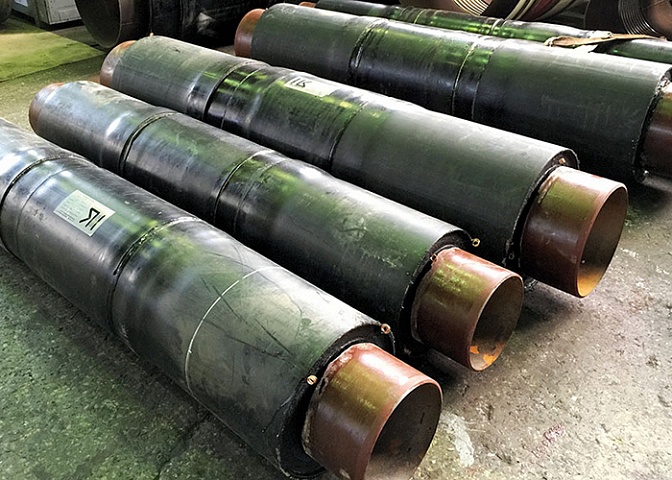

- SCU (BCD) type PPU is designed for use in pipelines with industrial thermal insulation of polyurethane foam in a polyethylene or galvanized sheath (shall be thermally insulated prior to installation in the pipeline). It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casings and internal guide supports and conductors of ROMS (remote on-line monitoring system). The bellows is thermally insulated. The inner surface of the BCD is waterproofed from ground water with a stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. Factory insulation of the branch pieces is not provided, there are two alignment sleeves for installation into them of polyethylene or galvanized sheaths and subsequent polyurethane foam thermal insulation of the branch pieces.

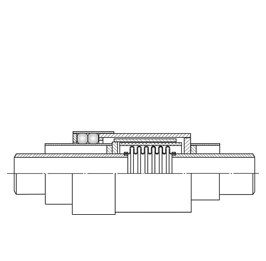

- SCU (BCD) PPU/OTs can be used for ground laying of pipeline, and underground laying in through channels and tunnels. It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casings, internal guide supports and conductors of ROMS. The bellows is thermally insulated. The inner surface of the BCD is waterproofed from ground water with a stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. BCD branch pieces are thermally insulated with polyurethane foam in a protective sheath of galvanized steel.

- SCU (BCD) type PPU/PE.I are not subject to flooding by ground, sewage or storm water and can be used for channelless laying of pipeline in dry soils with low level of ground water, and when installing them in crawlways equipped with drainage system. It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with limit stops, power casings, internal guide supports and conductors of ROMS. The bellows is thermally insulated. The inner surface of the BCD is waterproofed from ground water with a stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. BCD branch pieces are thermally insulated with polyurethane foam in a protective sheath. The casing of BCDs used for channelless laying may be additionally covered with a polyethylene heat-shrinkable sleeve.

- SCU (BCD) type PPU/PE.II is used for channelless laying of pipelines, and in cases of their laying in crawlways. The BCD can be used in wet soils with a high level of ground water and in crawlways that are not equipped with drainage system and subject to flooding by ground water, sewage or storm water. It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with internal guides, compression stroke limit stops and conductors of ROMS. The bellows is thermally insulated. The inner surface of the BCD is protected from ground water with a waterproof membrane and stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. Heat-shrinkable sleeves are installed above the BCD branch pieces for connection with polyethylene sheath of pre-insulated pipeline during installation. Heat-shrinkable sleeve of a larger diameter is welded to one of the sleeves by extruder welding, which acts as a protective casing, which, with a minimum gap, can move along the second sleeve of the BCD branch piece when it is deformed. BCD branch pieces are thermally insulated with polyurethane foam.

- SCU (BCD) type TGI.II is used for channelless laying of pipelines, and in cases of their laying in crawlways. The BCD can be used in wet soils with a high level of ground water and in crawlways that are not equipped with drainage system and subject to flooding by ground water, sewage or storm water. They can also be used in underground pipelines of heat networks with any thermal insulation. It consists of one or two bellows and welded neck branch pieces for welding to the pipeline, with internal guides, compression stroke limit stops and conductors of ROMS. The bellows is thermally insulated. The inner surface of the BCD is protected from ground water with a waterproof membrane and stuffing box packing. The outer surface of the bellows and branch pieces has an anti-corrosion waterproof coating. Heat-shrinkable sleeves are installed above the BCD branch pieces for connection with polyethylene sheath of pre-insulated pipeline during installation. Heat-shrinkable sleeve of a larger diameter is welded to one of the sleeves by extruder welding, which acts as a protective casing, which, with a minimum gap, can move along the second sleeve of the BCD branch piece when it is deformed. Polyurethane foam insulation of the branch pieces is not provided when manufacturing the BCD, it is done simultaneously with thermal insulation of joints of the BCD with the pipeline.

Сильфонные компенсационные устройства